Can you build kitchen cupboards yourself? Yes, you absolutely can build kitchen cupboards yourself! With a bit of planning, the right tools, and this detailed guide, you can tackle DIY kitchen cabinets and create beautiful, functional storage for your home. Building kitchen cabinet construction from scratch might seem daunting, but breaking it down into manageable steps makes it achievable for many homeowners. This guide will walk you through the entire process, from choosing your kitchen cabinet plans to the final cabinet finishing.

Learning cabinet making can be a rewarding woodworking project. You’ll gain valuable skills and have custom storage tailored precisely to your needs. This is your comprehensive guide to building kitchen cabinet construction from the ground up, transforming your kitchen with custom kitchen cupboards.

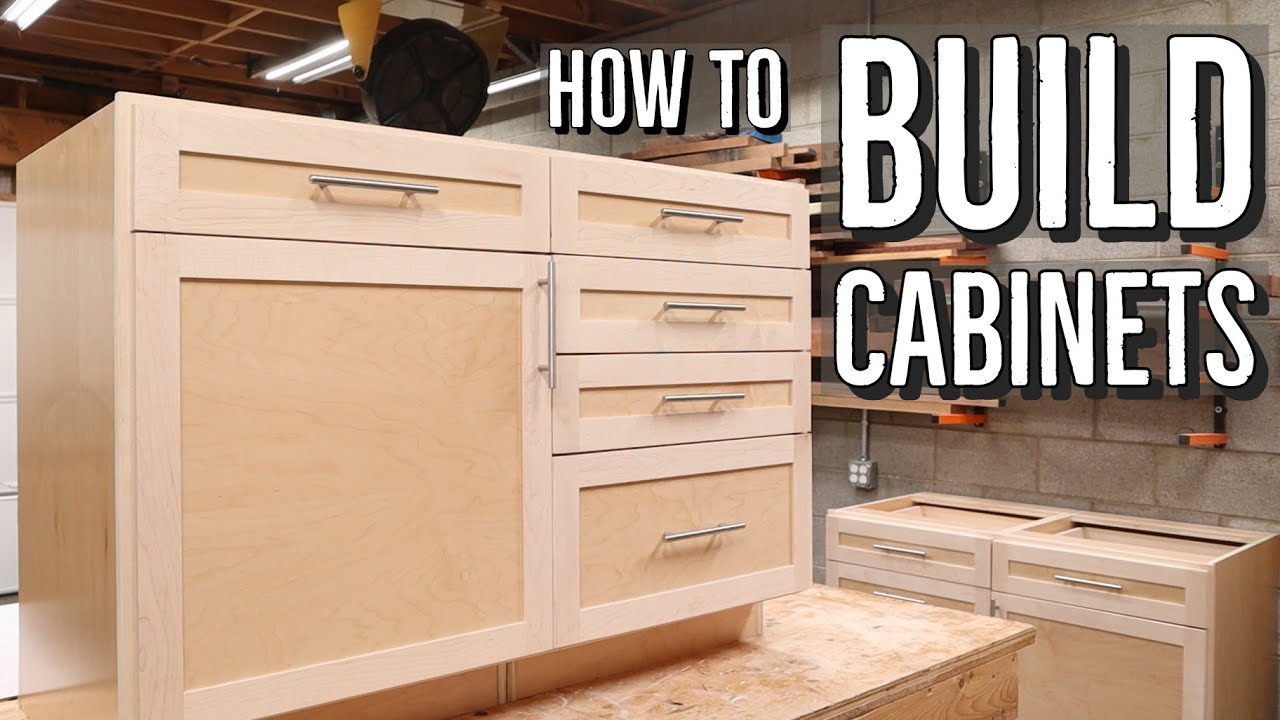

Image Source: i.ytimg.com

1. Planning Your Kitchen Cupboards

The first step in building your DIY kitchen cabinets is thorough planning. This phase is crucial for a successful project.

1.1 Measuring Your Space

Accurate measurements are non-negotiable. You need to know the exact dimensions of the space where your cabinets will go.

- Height: Measure from the floor to the ceiling. Also, measure from your countertop to the underside of the upper cabinets (if you’re building both). Standard countertop height is 36 inches.

- Width: Measure the total width of the wall or area where cabinets will be installed. Mark out the exact placement for each cabinet base and upper unit.

- Depth: Standard base cabinets are 24 inches deep. Upper cabinets are typically 12-13 inches deep. Consider how much space you have and what you’ll store.

- Obstructions: Note the location of windows, doors, electrical outlets, plumbing, and HVAC vents. These will affect cabinet placement and size.

1.2 Designing Your Layout

Once you have your measurements, you can start designing. Consider what you need your custom kitchen cupboards to do.

- Cabinet Types: Decide on the types of cabinets you need:

- Base Cabinets: These sit on the floor and support countertops. Common sizes include 30″, 33″, and 36″ widths. You’ll need corner cabinets, sink bases, and standard drawer/door cabinets.

- Upper Cabinets: These mount to the wall. Common depths are 12″ or 13″. Consider various widths and heights (e.g., 30″, 36″, 42″).

- Tall Cabinets: These can house pantries or appliances.

- Functionality: Think about how you use your kitchen. Where will you store pots, pans, dishes, and spices? A good layout makes cooking easier.

- Aesthetics: What style do you envision? Modern, traditional, rustic? This will influence your material and design choices.

1.3 Creating Kitchen Cabinet Plans

Detailed kitchen cabinet plans are your blueprint. You can find many free plans online or draft your own. Your plans should include:

- Dimensions: Exact width, height, and depth for each cabinet.

- Material List: What type of wood or plywood you’ll use for the boxes, doors, and drawers.

- Cut List: Precise measurements for each piece of wood you’ll need to cut.

- Joinery Details: How the cabinet parts will be connected (e.g., dados, rabbets, pocket screws).

- Hardware: List of hinges, drawer slides, handles, and knobs.

A simple spreadsheet or a dedicated woodworking software can help you organize this.

2. Selecting Materials

Choosing the right materials is key to the durability and appearance of your woodworking kitchen cabinets.

2.1 Cabinet Box Materials

The cabinet box is the main structure.

- Plywood: This is the most common and recommended material for cabinet boxes.

- Advantages: Strong, stable, less prone to warping than solid wood, available in various grades and thicknesses.

- Grades:

- Cabinet Grade (e.g., PureBond): Formaldehyde-free, smooth surfaces, suitable for visible areas.

- BC or AC Grade: Good for general construction, one side may have minor imperfections.

- Thickness:

- 3/4 inch (19mm): Standard for cabinet sides, bottoms, and tops. Provides excellent strength.

- 1/2 inch (12.7mm): Often used for cabinet backs or drawer bottoms.

- MDF (Medium-Density Fiberboard):

- Advantages: Smooth, paintable surface, consistent density.

- Disadvantages: Heavy, can sag over time if not supported well, susceptible to water damage, less durable than plywood. Generally not recommended for the primary structure of DIY kitchen cabinets.

- Solid Wood:

- Advantages: Beautiful, can be stained or painted, very strong.

- Disadvantages: More expensive, prone to expansion and contraction with humidity changes, which can lead to warping or cracking. Often used for face frames and doors.

2.2 Face Frame Materials

Face frames provide a mounting surface for doors and drawers and add structural rigidity.

- Hardwood: Oak, maple, cherry, or poplar are excellent choices. They are durable and take finishes well.

- Plywood: You can also use 3/4″ plywood for face frames, especially if you plan to paint them.

2.3 Door and Drawer Front Materials

This is where you can add a lot of visual appeal.

- Solid Wood: Offers a classic look and can be stained or painted.

- Plywood: Can be used for Shaker-style doors or painted doors.

- MDF: Excellent for painted doors due to its smooth surface.

2.4 Hardware Selection

- Drawer Slides: Full-extension, ball-bearing slides are recommended for smooth operation and full access to drawers.

- Hinges: Various types exist (e.g., concealed, semi-concealed, butt hinges). Concealed hinges are popular for a clean look.

- Handles and Knobs: Choose based on your kitchen’s style.

3. Essential Tools for Cabinet Making

Having the right tools makes the job much easier and produces better results.

3.1 Cutting Tools

- Table Saw: Essential for ripping plywood and cutting precise dadoes and rabbets for cabinet joinery. A good quality table saw with a sharp blade is a must.

- Miter Saw/Chop Saw: For accurately cutting cabinet parts to length and making precise angle cuts.

- Circular Saw: Can be used with a guide for breaking down large plywood sheets if a table saw isn’t available, but less precise.

- Jigsaw: Useful for cutting curves or access holes.

3.2 Assembly Tools

- Drill/Driver: For drilling pilot holes, driving screws, and installing hardware.

- Pocket Hole Jig (e.g., Kreg Jig): An extremely useful tool for creating strong, hidden joints for face frames and assembling cabinet boxes.

- Clamps: You’ll need various types and sizes of clamps (bar clamps, pipe clamps, spring clamps) to hold pieces together while glue dries.

- Orbital Sander: For smoothing surfaces before finishing.

- Measuring Tape and Square: For accurate measurements and ensuring squareness.

- Level: To ensure cabinets are installed plumb and level.

3.3 Safety Gear

- Safety Glasses: Always wear eye protection.

- Hearing Protection: For noisy power tools.

- Dust Mask: Especially important when cutting and sanding wood or MDF.

4. Building the Cabinet Boxes

The cabinet box is the backbone of your DIY kitchen cabinets.

4.1 Cutting Your Plywood

Using your kitchen cabinet plans and cut list, carefully cut all the pieces for your cabinet boxes from 3/4″ plywood.

- Accuracy: Measure twice, cut once. Ensure all cuts are square.

- Grain Direction: Pay attention to grain direction for stability, especially on the bottom and back panels.

4.2 Creating Joinery

Strong cabinet joinery is vital for durability. Common methods include:

- Dadoes and Rabbets:

- Dado: A groove cut across the grain of the wood. Used to seat shelves or cabinet backs.

- Rabbet: A groove cut along the edge of the wood. Used to house cabinet backs or join cabinet sides to the bottom.

- You’ll use your table saw with a dado blade or multiple passes of a standard blade to create these.

- Pocket Holes: A fast and strong method, especially for attaching face frames and assembling boxes if dadoes are not used.

- Butt Joints with Screws and Glue: While simple, this method is generally less strong and visually appealing than dadoes or pocket holes for cabinet construction. Reinforce with glue.

4.3 Assembling the Box

Let’s assume you are building a standard base cabinet box.

- Attach Sides to Bottom: Apply wood glue to the edges where the side panels meet the bottom panel.

- If using dadoes, slide the side panels into the dadoes on the bottom panel.

- If using pocket holes, drill pocket holes on the bottom edges of the side panels and drive screws into the bottom panel.

- Clamp securely and ensure the assembly is square.

- Attach the Top (or Cleats): For base cabinets, you might attach a top panel or, more commonly, cleats across the top edges of the sides for support and to attach the countertop.

- Cleats: Cut 3/4″ plywood or solid wood strips. Glue and screw them to the top edges of the cabinet sides. Ensure they are flush with the outside edges of the sides.

- Install the Back Panel:

- Cut a piece of 1/4″ or 1/2″ plywood for the back.

- Apply glue to the back edges of the cabinet sides, top, and bottom.

- Slide the back panel into the rabbets or position it flush against the back edges.

- Secure with screws or brad nails. Ensure the cabinet remains square as you attach the back.

- Squareness Check: Measure the diagonals of the cabinet box. If they are equal, the box is square.

4.4 Building Drawer Boxes

Drawer boxes are usually made with 1/2″ or 3/4″ plywood or solid wood.

- Cut Drawer Sides, Front, Back, and Bottom: Based on your kitchen cabinet plans.

- Joinery:

- Dado and Rabbet: Cut grooves in the sides for the drawer bottom, and dadoes in the front and back for the sides.

- Dovetail Joints: A highly skilled and strong joinery method, often used in high-end woodworking kitchen cabinets.

- Box Joints: Another strong interlocking joint.

- Pocket Holes: A quick and effective method for drawer construction.

- Assemble: Glue and screw the sides, front, and back together. Slide the drawer bottom into the grooves. Ensure the drawer box is square before the glue dries.

5. Building Face Frames

Face frames add strength and a finished look to your DIY kitchen cabinets. They also provide a surface to mount doors and drawers.

5.1 Material Choice

Use hardwood for face frames if you plan to stain them. Poplar or pine is good for painted cabinets.

5.2 Cutting the Pieces

Based on your kitchen cabinet plans, cut stiles (vertical pieces) and rails (horizontal pieces).

- Face Frame Size: The face frame typically extends slightly beyond the cabinet box, often by 1/4″ to 1/2″ on the front, sides, and bottom. The top is usually flush with the cabinet box to allow for countertop overhang.

5.3 Joinery for Face Frames

- Pocket Holes: The most common and easiest method for DIYers. Drill pocket holes on the back of the rails and attach them to the stiles.

- Mortise and Tenon: A traditional and very strong joinery method, but requires more advanced woodworking skills.

- Dowels: Can also be used for strong joints.

5.4 Assembling the Face Frame

- Lay out your stiles and rails on a flat surface.

- Apply glue to the joints.

- Use your pocket hole jig or chosen joinery method to connect the pieces.

- Clamp firmly and check for squareness.

5.5 Attaching Face Frames to Cabinet Boxes

- Positioning: Center the face frame on the cabinet box, ensuring the desired overhang.

- Securing: Apply wood glue to the front edges of the cabinet box.

- Fastening: Drive screws from the inside of the cabinet box into the back of the face frame. Alternatively, use brad nails from the front of the face frame into the cabinet box, but this requires filling the nail holes.

6. Constructing Doors and Drawer Fronts

These components significantly impact the look of your custom kitchen cupboards.

6.1 Door Styles

- Flat Panel (Slab) Doors: Simple and modern, made from a single piece of wood or plywood.

- Shaker Doors: A popular style with a flat center panel surrounded by a frame (stiles and rails).

- Raised Panel Doors: Feature a center panel that is thicker in the middle and tapers to the edges, offering a more traditional look. This requires specialized router bits.

6.2 Building Shaker Doors (Example)

- Cut Rails and Stiles: Cut your chosen wood (hardwood is best for stain) to the required lengths for the outer frame.

- Create Joinery:

- Dadoes: Cut dadoes in the ends of the stiles where the rails will sit.

- Rabbets: Cut rabbets on the inside edges of the stiles and rails to house the center panel.

- Cut Center Panel: Cut your plywood or solid wood for the center panel. Ensure it fits snugly into the rabbets.

- Assemble: Apply glue, insert the center panel into the rabbets, and assemble the frame using the dadoed rails and stiles. Clamp securely and check for squareness.

6.3 Building Drawer Fronts

Drawer fronts are essentially small doors. You can make them as slab fronts or frame-and-panel designs.

- Slab Drawer Fronts: Cut a piece of plywood or solid wood to the exact size needed to cover the drawer box opening.

- Frame-and-Panel Drawer Fronts: Similar construction to Shaker doors.

7. Drawer Slide and Hinge Installation

Precise installation is key for smooth operation.

7.1 Drawer Slide Installation

- Cabinet Slides: Mount one part of the drawer slide to the inside of the cabinet box. Use a level and measuring tape to ensure they are parallel and at the correct height.

- Drawer Slides: Mount the corresponding part of the slide to the side of the drawer box. Follow the manufacturer’s instructions carefully for precise placement.

- Test: Slide the drawer in and out to ensure smooth operation before permanently attaching.

7.2 Hinge Installation

- Concealed Hinges: These require precise drilling of cup holes in the doors and mortises in the cabinet face frame or sides. Use a template or jig for accuracy.

- Cabinet Hinges: For traditional hinges, mark the placement, drill pilot holes, and screw them in.

- Alignment: Ensure doors hang straight and have even gaps. Adjust hinges as needed.

8. Cabinet Finishing

The finishing stage protects your woodworking kitchen cabinets and gives them their final look.

8.1 Surface Preparation

- Sanding: Sand all surfaces thoroughly. Start with a coarser grit (e.g., 100-120) to remove imperfections and progress to finer grits (e.g., 180-220) for a smooth finish.

- Cleaning: Wipe down all surfaces with a tack cloth or a damp cloth to remove dust.

8.2 Applying Stain (Optional)

- If you’re staining, apply a pre-stain conditioner, especially on woods like pine or maple, to ensure even absorption.

- Apply stain with a brush or cloth, wiping off excess according to the product instructions.

8.3 Applying a Topcoat (Varnish, Polyurethane, Lacquer)

- Purpose: Protects the wood from moisture, stains, and wear.

- Application: Apply thin, even coats using a high-quality brush, foam roller, or sprayer.

- Sanding Between Coats: Lightly sand with very fine grit sandpaper (e.g., 320-400) between coats to knock down any dust nibs and create a smoother finish.

- Number of Coats: Apply 2-3 coats for good durability.

8.4 Finishing Doors and Drawer Fronts

Finish doors and drawer fronts separately before attaching them to the cabinets. This allows for easier access to all surfaces.

9. Installing Kitchen Cupboards

The final step is mounting your completed DIY kitchen cabinets.

9.1 Mounting Upper Cabinets

- Locate Studs: Use a stud finder to locate wall studs where the cabinets will be attached. Mark their centers.

- Mark Mounting Height: Use a level to draw a level line on the wall at the desired height for the bottom of your upper cabinets (typically 54″ from the floor, leaving 18″ or 24″ above the countertop).

- Secure Cabinet:

- Lift the cabinet into place, resting it on a temporary support if needed.

- Align the cabinet’s back edge with your marked line.

- Drive 2.5″ to 3″ wood screws through the back of the cabinet into the wall studs. Use at least two screws per stud.

- Check for level and plumb.

9.2 Mounting Base Cabinets

- Positioning: Place the base cabinet in its intended location.

- Leveling: Use shims under the cabinet to make it level and plumb.

- Securing: Screw through the back of the cabinet into wall studs, similar to upper cabinets. You can also toe-nail from the bottom corners into the floor for added stability if desired.

9.3 Installing Countertops

Once all cabinets are securely mounted, you can install your countertops. This is often a separate project, but ensure your cabinets are perfectly level and securely fastened to support the countertop weight.

9.4 Cabinet Hardware Installation

- Handles and Knobs: Mark the desired locations on the doors and drawer fronts. Drill pilot holes and attach the hardware. Use a jig for consistent placement, especially on multiple doors.

Frequently Asked Questions (FAQ)

Q1: What is the best wood for DIY kitchen cabinets?

A1: For cabinet boxes, 3/4″ plywood (cabinet grade) is highly recommended due to its stability and strength. For face frames, doors, and drawer fronts, hardwoods like maple, oak, or cherry are excellent choices for stained finishes, while poplar or MDF are good for painted finishes.

Q2: Can I build kitchen cabinets with just basic tools?

A2: While you can start with basic tools, a table saw is almost essential for accurately cutting plywood and creating joinery like dadoes and rabbets. A miter saw or even a good hand saw and miter box can work for basic cuts, but precision will be a challenge. A pocket hole jig significantly simplifies assembly.

Q3: How thick should plywood be for cabinet boxes?

A3: 3/4″ (19mm) plywood is the standard thickness for cabinet sides, tops, and bottoms. 1/4″ or 1/2″ plywood is typically used for cabinet backs and drawer bottoms.

Q4: What kind of joinery should I use for cabinet construction?

A4: For DIYers, pocket holes offer a fast and strong way to assemble cabinet boxes and face frames. Dadoes and rabbets are traditional and strong, requiring a table saw. Dovetail joints are the strongest and most beautiful but are more advanced.

Q5: How do I ensure my cabinets are square?

A5: The best way to check for squareness is to measure the diagonals of the cabinet box. If the two diagonal measurements are equal, the box is perfectly square.

Q6: How far apart should wall studs be?

A6: Standard wall studs are typically spaced 16 inches or 24 inches on center. Always use a stud finder to locate them accurately when mounting cabinets.

Building kitchen cabinet construction from scratch is a rewarding journey. By following these steps, paying attention to detail, and using quality materials, you can create beautiful and functional custom kitchen cupboards that will serve you well for years to come. Enjoy your woodworking kitchen cabinets project!