Image Source: www.aresheng.com.tw

How To Put In A Kitchen Sink Drain: Step-by-Step

Can you install a kitchen sink drain yourself? Yes, with the right tools and a little patience, you can certainly install a kitchen sink drain yourself. Who is this guide for? This guide is for homeowners who are comfortable with basic DIY tasks and want to save money by tackling this plumbing project themselves.

Replacing or installing a new kitchen sink drain might seem like a daunting task, but it’s actually quite manageable for the average homeowner. This process is a key part of kitchen sink installation, and getting it right ensures your sink functions smoothly and prevents costly water damage. We’ll guide you through each step, from gathering your materials to the final leak testing.

What You’ll Need: Your Toolkit for a Successful Drain Installation

Before you start, gather all your tools and materials. Having everything on hand will make the job go much smoother and faster.

Essential Tools:

- Adjustable Wrench: For tightening and loosening various fittings.

- Pipe Wrench: For a more secure grip on pipes.

- Plumber’s Putty: A pliable, waterproof sealant essential for sealing the drain.

- Screwdriver Set: For any screws you might encounter.

- Bucket: To catch any residual water in the pipes.

- Rags or Towels: For cleaning up spills.

- Safety Glasses: To protect your eyes from debris.

- Gloves: To keep your hands clean and protected.

- Utility Knife or PVC Cutter: For trimming PVC pipes if necessary.

- Measuring Tape: To ensure proper pipe lengths.

- Optional: Plumber’s Tape (PTFE Tape): Can be used on threaded connections for a better seal, though often not needed with rubber gaskets.

Essential Materials:

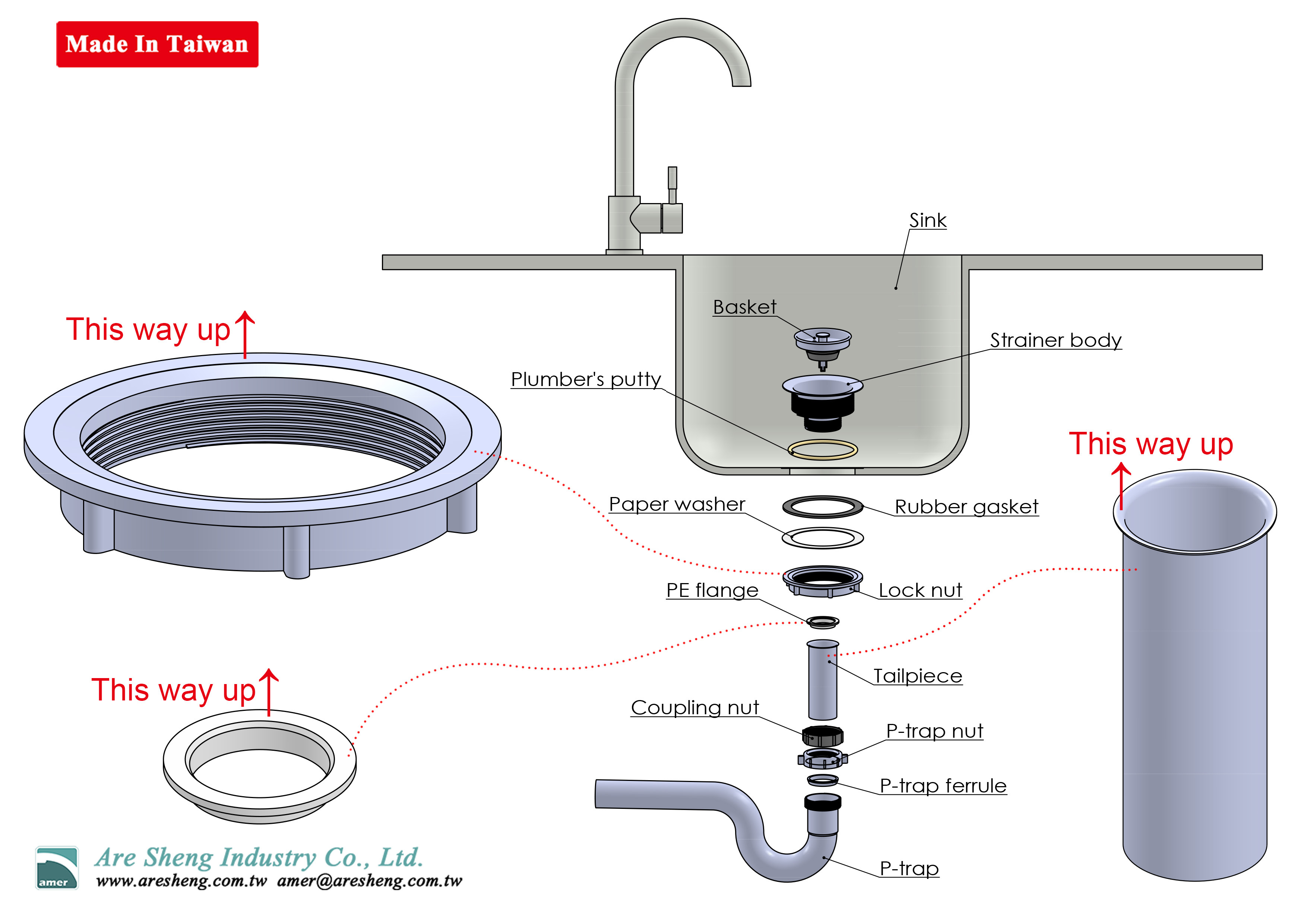

- Sink Strainer Assembly: This includes the drain flange, gasket, and locknut. The flange sits inside the sink, and the strainer basket fits into it.

- Tailpiece: A short piece of pipe that extends from the bottom of the sink drain assembly.

- P-trap Kit: This U-shaped pipe prevents sewer gases from entering your home. It connects your sink drain to the drain pipe connection in the wall.

- Connecting Nuts and Washers: These are usually included with the P-trap kit and tailpiece.

- Threaded Pipe Adapter (if connecting to existing plumbing): This might be needed if your existing drain pipe has a different connection type.

- New Sink (if applicable): Ensure it has the correct drain opening size.

Step 1: Preparing the Sink for Drain Installation

This is the foundational step for any kitchen sink installation.

Removing the Old Drain (If Applicable)

If you’re replacing an old drain, start by carefully removing it.

- Clear the Area: Remove everything from under the sink. Place a bucket underneath the existing drain assembly to catch any water.

- Loosen the P-trap: Use an adjustable wrench to loosen the slip nuts connecting the P-trap to the tailpiece and the wall drain pipe. Be prepared for a small amount of water to drain out.

- Disconnect the Tailpiece: Loosen the slip nut connecting the tailpiece to the sink drain assembly.

- Remove the Old Strainer: From the top of the sink, try to unscrew the old strainer basket. If it’s stuck, you might need to use pliers or a screwdriver to help loosen it. From underneath, loosen the locknut that holds the drain flange in place. Once the locknut is off, you should be able to lift the old drain assembly out from the top.

- Clean the Sink Opening: Thoroughly clean the sink opening where the drain was. Remove any old plumber’s putty or sealant. A putty knife can be helpful here.

Preparing the New Sink

If you’re working with a new sink, ensure the drain opening is clean and free of any manufacturing residue.

Step 2: Assembling the Sink Strainer and Drain Flange

This is where the drain flange and plumber’s putty come into play.

- Apply Plumber’s Putty: Take a generous amount of plumber’s putty and roll it into a snake-like rope, about ½ inch thick.

- Seal the Flange: Press this rope of putty firmly around the underside of the drain flange. Make sure it creates a continuous seal. This putty will help in sealing the drain effectively.

- Insert the Flange: From the top of the sink, press the drain flange down into the drain opening, ensuring the putty makes good contact with the sink surface.

- Attach the Gasket and Locknut: From underneath the sink, slide the rubber gasket (usually tapered side up) over the threaded part of the flange. Then, thread the locknut onto the flange.

- Tighten the Locknut: Hand-tighten the locknut first. Then, use an adjustable wrench or pliers to tighten it further. Be careful not to overtighten, as this can crack the sink. The goal is to compress the putty and gasket enough to create a watertight seal. You’ll see some putty squeeze out from under the flange.

Step 3: Connecting the Tailpiece

The tailpiece is the next component to attach.

- Prepare the Tailpiece: The tailpiece is usually a straight pipe that extends downwards from the drain flange assembly. It may need to be cut to the correct length using a hacksaw or PVC cutter. Measure the distance from the bottom of the drain flange to where your P-trap will connect, allowing for the P-trap’s bends.

- Attach the Tailpiece: Slide a slip nut and a washer onto the threaded end of the tailpiece. Then, thread the tailpiece onto the bottom of the sink strainer assembly. Hand-tighten it.

- Position and Tighten: Align the tailpiece so it’s pointing in the general direction of your wall drain pipe. Once aligned, use an adjustable wrench to snug up the connection. Don’t overtighten.

Step 4: Connecting the P-trap

The P-trap is crucial for preventing sewer odors. This step involves the drain pipe connection.

- Assemble the P-trap: Most P-trap kits come with a U-shaped pipe and two connecting pipes, along with slip nuts and washers. Slide a slip nut and a washer onto each end of the U-shaped pipe.

- Connect to the Tailpiece: Slide a slip nut and a washer onto the free end of the tailpiece. Now, connect one end of the P-trap to the tailpiece. Ensure the washer is properly seated against the tailpiece. Hand-tighten the slip nut.

- Connect to the Wall Drain: Align the other end of the P-trap with the drain pipe connection in the wall. This might be a threaded fitting or a piece of PVC pipe. Slide a slip nut and washer onto the end of the P-trap that connects to the wall. Make sure the washer is correctly positioned. Hand-tighten the slip nut.

- Adjust and Tighten: Adjust the P-trap so that it has a slight downward slope from the sink towards the wall drain, helping water flow. Once positioned correctly, use an adjustable wrench to tighten all the slip nuts. Again, snug them up but avoid overtightening.

Step 5: The Garbage Disposal Connection (If Applicable)

If you have a garbage disposal, the garbage disposal connection needs to be handled.

- Prepare the Disposal Inlet: If your garbage disposal is already installed, you’ll need to connect the tailpiece (or sometimes a separate pipe) to the disposal’s inlet port. If you’re installing both the sink and disposal at the same time, the disposal will typically mount directly to the underside of the sink flange.

- Mounting the Disposal: If installing simultaneously, follow the manufacturer’s instructions for mounting the garbage disposal to the sink flange. This usually involves a mounting bracket and retaining ring.

- Connecting the Drain: Once the disposal is mounted, its outlet will connect to the P-trap. You might use a straight tailpiece or a specialized disposal outlet pipe. Attach a slip nut and washer to the disposal outlet, then connect it to the appropriate arm of your P-trap. Hand-tighten, then snug with a wrench.

Step 6: Leak Testing Your New Drain

This is the critical final step to ensure your work is watertight.

- Check All Connections: Visually inspect every connection point: where the flange meets the sink, the tailpiece to the flange, the tailpiece to the P-trap, and the P-trap to the wall drain. Ensure all slip nuts and locknuts are snug.

- Run Water: Place a bucket under the P-trap and tailpiece. Turn on the cold water tap and let it run for a minute or two.

- Inspect for Leaks: Carefully examine all connection points for any signs of dripping or moisture. Use a dry rag to wipe each joint.

- Test with Hot Water and Disposal: If there are no leaks with cold water, run hot water for a minute. If you have a garbage disposal, run it with cold water for about 30 seconds. This is another crucial part of leak testing.

- Address Any Leaks: If you find any leaks:

- Slight Tightening: Try slightly tightening the leaking slip nut or locknut. Sometimes a ¼ turn is all that’s needed.

- Re-seating Washers: If tightening doesn’t work, the washer might be misaligned or damaged. Disassemble the connection, re-seat the washer, and reassemble.

- Plumber’s Putty: If the leak is at the drain flange, you might need to remove the flange, clean off the old putty, apply fresh plumber’s putty, and re-tighten. This is important for sealing the drain properly.

- Plumber’s Tape: For threaded connections (less common with modern P-traps but possible), you might need to add plumber’s tape to the threads.

Important Considerations and Tips

- Sink Material: Be extra gentle when tightening connections on porcelain or ceramic sinks, as they can crack if too much force is applied. Stainless steel sinks are more forgiving.

- Pipe Material: Most modern kitchen drains use PVC or ABS plastic pipes. Ensure your new components are compatible.

- Drain Pipe Connection Type: Be aware of how your existing drain pipe in the wall is configured. It might be a threaded metal pipe or a PVC pipe with a glued or rubber-gasketed connection. Your P-trap kit will need to adapt to this.

- Ventilation: Your plumbing system has a vent pipe that allows air into the drain system, helping water flow smoothly and preventing sewer gases from backing up. Ensure your P-trap is connected to the main drain line, which is typically vented.

- Code Compliance: In some areas, plumbing work may require permits and inspections. Check with your local building department for any specific regulations.

- Garbage Disposal Weight: If you’re installing a garbage disposal, it adds significant weight to the sink. Ensure your sink and countertop can support it.

Troubleshooting Common Issues

| Problem | Cause | Solution |

|---|---|---|

| Leak at Drain Flange | Insufficient plumber’s putty; loose locknut | Remove, reapply plumber’s putty, tighten locknut securely. |

| Leak at Slip Nut | Loose slip nut; damaged or missing washer | Tighten slip nut; ensure washer is present and correctly seated; replace washer if damaged. |

| Slow Draining | Partial clog in P-trap or tailpiece | Disassemble P-trap and clean out any debris; check tailpiece for obstructions. |

| Gurgling Sounds | Improper venting; air trapped in pipes | Ensure proper slope of pipes; check plumbing vent stack for blockages (usually requires professional help). |

| Sewer Odors | Dry P-trap; leak in the drain system | Run water regularly; check all connections for leaks and seal as needed. |

| Disposal Outlet Leak | Loose connection; damaged gasket/washer | Tighten connection; replace gasket or washer if necessary. |

Frequently Asked Questions (FAQ)

Q1: How much plumber’s putty do I need?

A1: You need enough plumber’s putty to create a continuous bead around the underside of the drain flange. A rope about ½ inch thick and encircling the flange is usually sufficient.

Q2: Do I need plumber’s putty if my sink strainer has a rubber gasket?

A2: Yes, even with a rubber gasket, plumber’s putty is essential for sealing the drain at the flange. The gasket creates a primary seal, while the putty fills any microscopic imperfections in the sink surface or the flange itself, ensuring a watertight seal.

Q3: Can I use silicone caulk instead of plumber’s putty?

A3: While silicone caulk is a sealant, it’s generally not recommended for sealing the drain flange directly against the sink. Plumber’s putty is specifically designed for this purpose and remains pliable, allowing for slight movement without breaking the seal. Silicone can become too rigid.

Q4: How tight should I make the connections?

A4: Hand-tighten all connections first, then use an adjustable wrench to snug them up. Overtightening can strip threads or crack plastic pipes and fittings. A snug fit that prevents leaks is all that’s needed.

Q5: What if my P-trap doesn’t line up with the wall drain pipe connection?

A5: P-trap kits are designed with some flexibility. You can adjust the angles of the connecting pipes. If it’s still too far off, you might need to cut and glue new PVC pipes to extend or reposition the drain pipe connection in the wall, or use a different P-trap configuration. This may require more advanced plumbing skills.

Q6: Do I need to replace the whole sink drain assembly when I replace the sink?

A6: It’s highly recommended. While you might be able to reuse the old tailpiece or P-trap if they are in good condition, the sink strainer assembly (flange, gasket, locknut) is best replaced with the sink to ensure a good seal and to avoid potential future leaks from aged components.

Completing your kitchen sink installation by properly installing the drain is a rewarding DIY task. By following these steps carefully and performing thorough leak testing, you can ensure your new sink drains effectively and without issues for years to come.